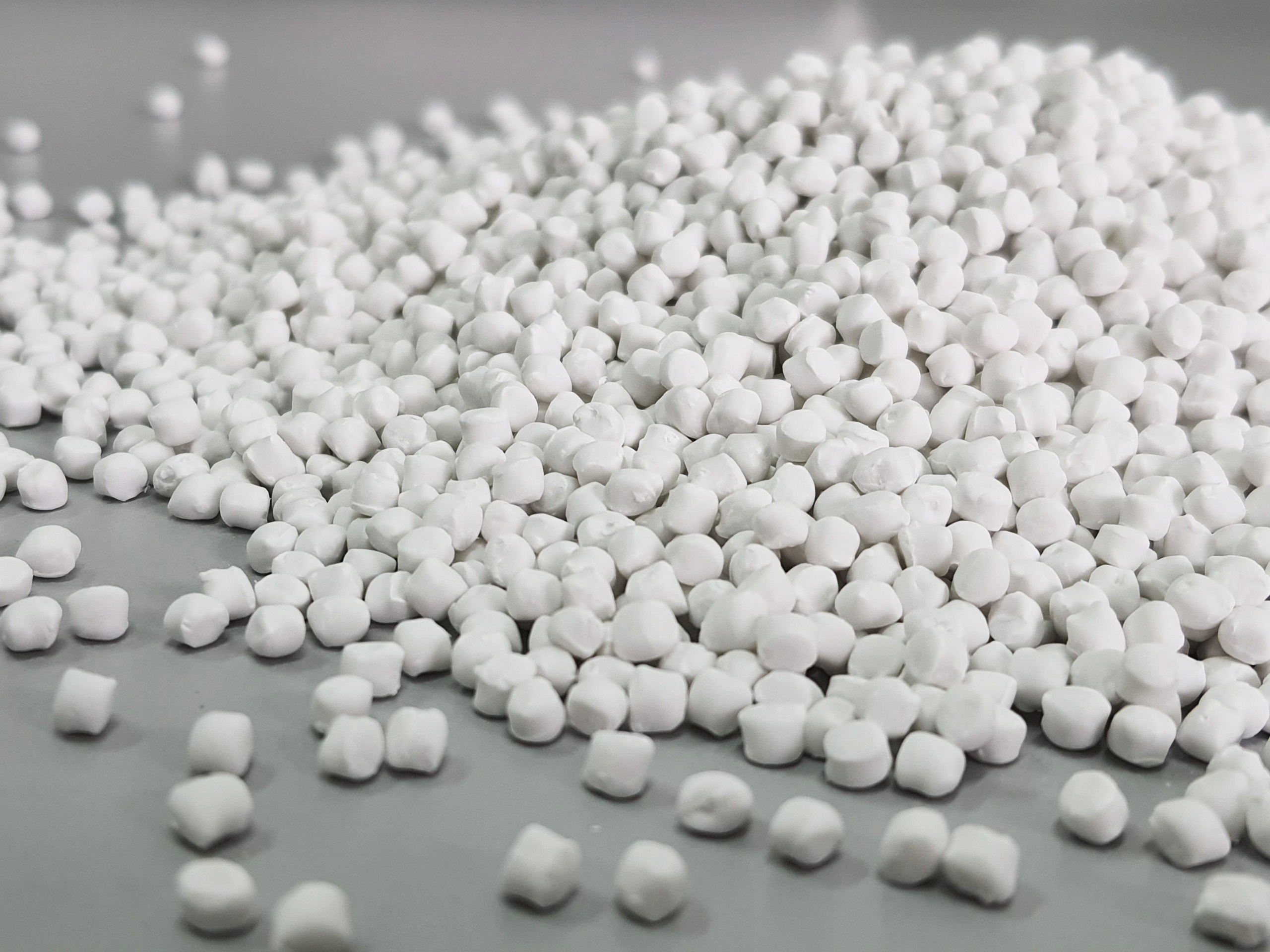

PP Non-woven Filler Masterbatch is a valuable additive used in the non-woven fabric industry to enhance product properties and reduce production costs. By incorporating calcium carbonate (CaCO3) into polypropylene (PP) resin, this masterbatch offers several significant benefits:

Key Benefits:

1. Cost Reduction:

Lower Material Cost: Calcium carbonate is a cost-effective filler compared to virgin PP resin, leading to reduced material costs.

Increased Production Efficiency: Improved processability and flow properties can lead to faster production cycles and higher output.

2. Improved Product Properties:

Enhanced Mechanical Properties: Increased stiffness, strength, and durability of the non-woven fabric.

Improved Surface Finish: Smoother and more aesthetically pleasing surface.

Enhanced Thermal Properties: Improved heat resistance and thermal stability.

3. Environmental Benefits:

Reduced Environmental Impact: By using less virgin plastic, manufacturers contribute to a more sustainable production process and reduced carbon footprint.

Applications in Non-Woven Fabrics:

- Medical and Hygiene Products: Used in applications like surgical gowns, masks, diapers, and sanitary napkins to improve strength, softness, and absorbency.

- Geotextiles: Enhances the mechanical properties of geotextiles used in civil engineering applications, such as road construction and soil stabilization.

- Agricultural Fabrics: Improves the durability, UV resistance, and water permeability of agricultural fabrics like mulch films and crop covers.

- Industrial Fabrics: Used in filtration, insulation, and packaging applications to improve strength, thermal resistance, and filtration efficiency.

Considerations for Using PP non-woven Filler Masterbatch:

- Filler Loading: The amount of filler added to the PP resin can significantly impact the properties of the final product.

- Filler Particle Size and Distribution: The size and distribution of the filler particles influence the mechanical properties and surface finish of the non-woven fabric.

- Compatibility with Other Additives: The filler masterbatch should be compatible with other additives used in the non-woven production process, such as antioxidants, UV stabilizers, and flame retardants.

By carefully selecting and incorporating PP non-woven Filler Masterbatch into the non-woven fabric production process, manufacturers can achieve significant improvements in product quality, cost-effectiveness, and environmental sustainability.

Contact us at Vico Plastic Co., Ltd. to learn more about our products

VICO PLASTIC VIETNAM CO., LTD

(Truong An Industrial Zone, An Khanh, Hoai duc, Hanoi, Vietnam)

Reviews

There are no reviews yet.