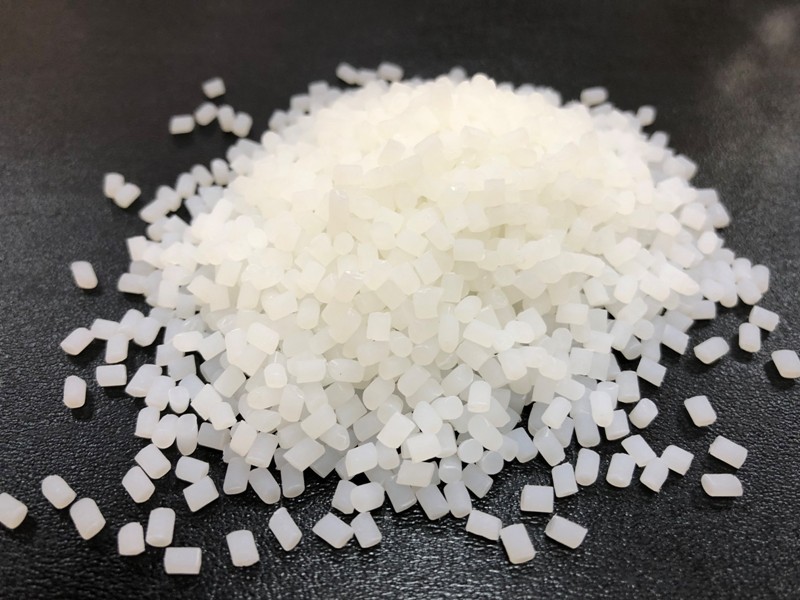

Anti-Static ADDITIVES

Anti-static additives are chemical compounds added to plastic materials to reduce or eliminate the buildup of static electricity on their surfaces. Static electricity can cause a variety of problems, including:

- Dust and debris attraction: Static electricity can attract dust, dirt, and other particles, making it difficult to clean and maintain products.

- Electrostatic discharge (ESD): Static electricity can cause sparks, which can damage electronic components.

- Processing difficulties: Static electricity can interfere with processes like printing, coating, and assembly.

How Anti-Static Additives Work:

- Increasing surface conductivity: They increase the surface conductivity of the plastic material, allowing static charges to dissipate more easily.

- Absorbing moisture: They attract moisture from the air, which helps to neutralize static charges.

- Ionizing the air: They ionize the air surrounding the plastic, neutralizing static charges.

Types of Anti-Static Additives:

There are two main types of anti-static additives:

- Internal anti-static agents: These are added to the plastic during the manufacturing process and migrate to the surface to provide long-lasting anti-static protection.

- External anti-static agents: These are applied to the surface of the plastic product after manufacturing, providing short-term anti-static protection.

Applications of Anti-Static Additives:

Anti-static additives are used in a wide range of industries, including:

Benefits of Using Anti-Static Additives:

- Reduce the static charge build-up on plastic surface

- Work with just a small amount

- Environmentally friendly

- Permanent effectiveness

- Improved product quality and performance

- Enhanced product appearance

- Reduced production downtime

- Increased product lifespan

Improved worker safety

- Electronics: To protect electronic components from electrostatic discharge.

- Packaging: To prevent static-related issues during packaging and transportation.

- Textiles: To improve the feel and performance of fabrics.

- Automotive: To reduce static buildup on car interiors and exteriors.

In conclusion, anti-static additives are essential for ensuring the quality and performance of plastic products. By effectively mitigating static electricity, these additives help prevent product damage, improve processing efficiency, and enhance the overall aesthetic appeal of finished products.

To learn more about how anti-static additives can benefit your specific needs, contact Vico Plastic today.

VICO PLASTIC VIETNAM CO.,LTD

(Truong An Industrial Zone, An Khanh, Hoai duc, Hanoi, Vietnam)

Reviews

There are no reviews yet.