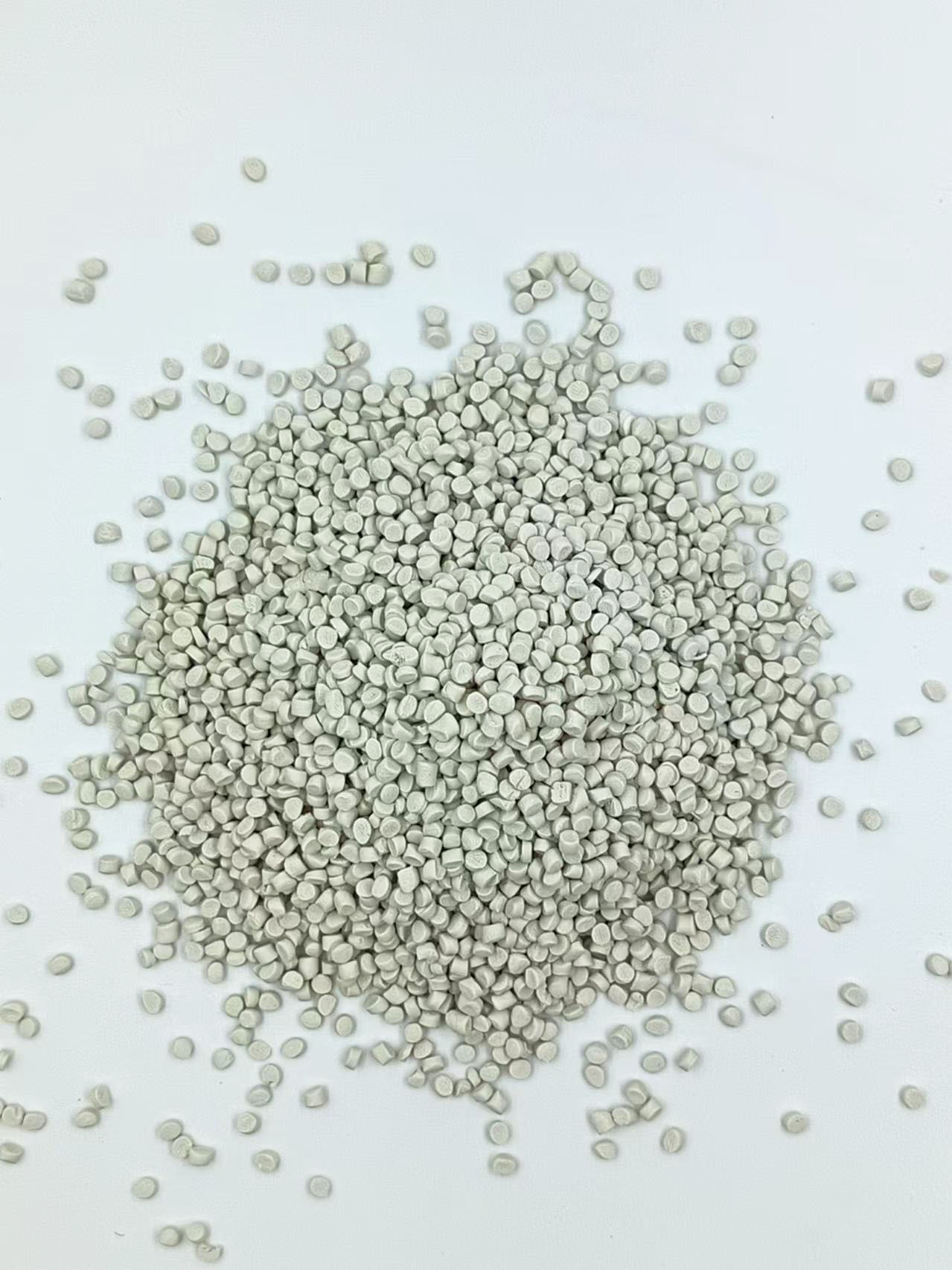

Desiccant masterbatch is an advanced functional masterbatch developed to solve the moisture problem. A desiccant is a substance designed to eliminate humidity and enhance extrusion and injection processes. A desiccant masterbatch gives a complete solution to the processor so as to reduce or remove undesired moisture.

Moisture can be present in raw materials such as hygroscopic polymers, fillers, and pigments, recycle granules

This masterbatch is used in eliminating moisture in virgin and recycled LD, LLDPE, HM, PP etc.

Desiccant masterbatch is suitable for blown film extrusion, injection molding, and blow molding process. It is used directly by mixing the masterbatch and the damp plastic material uniformly.

An anti-UV additive is used to protect plastic materials from UV radiation. These additives work by absorbing or scattering the UV rays, preventing them from penetrating the plastic and causing damage. Anti-UV additives can be added to plastics during the production process, or they can be applied as a coating to the surface of the material.

Types of Anti-UV Additives

There are two main types of anti-UV additives:

- Organic UV absorbers: These compounds absorb UV radiation and dissipate the energy as heat. They are effective in protecting plastics from UV damage, but they can degrade over time, especially at high temperatures.

- Inorganic UV absorbers: These compounds reflect UV radiation and are more stable than organic UV absorbers. However, they can be less effective at absorbing UV radiation.

In conclusion, anti-UV Additive is a crucial additive for protecting plastic products from the harmful effects of UV radiation. By incorporating this innovative

To learn more about how anti-UV Additive can benefit your specific needs, please contact Vico Plastic today.

VICO PLASTIC VIETNAM CO., LTD

(Truong An Industrial Zone, An Khanh, Hoai duc, Hanoi, Vietnam)

Reviews

There are no reviews yet.