Thermoforming creates customized shaped plastic sheets by heating, softening and vacuuming to create end-products with molded shapes.

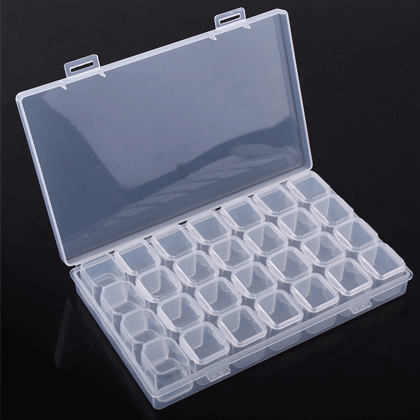

Food packaging

Common applications

Our solutions

Our solutions

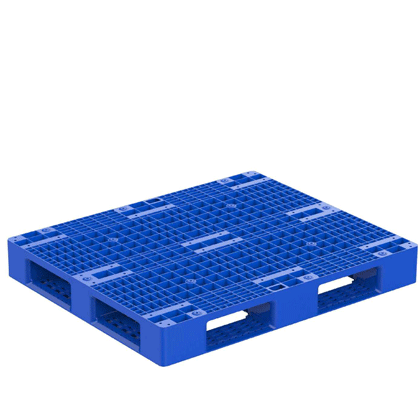

Manufacturing Industry

Common applications

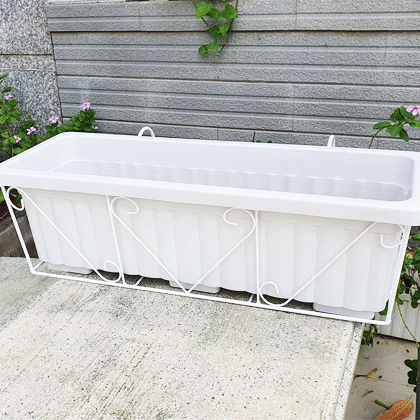

Household Appliances

Common applications