In blown films, input plastic material is melted and inflated into bubble form, then rolled into finished film rolls or used for the next processing steps. The level of films thickness and clarity depends on the end-products’ requirements.

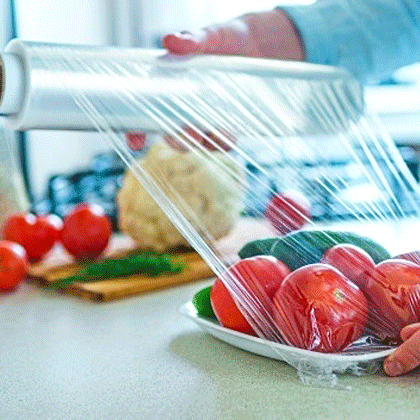

Retail industry

Common applications

Our solutions

Our solutions

Medical industry

Common applications

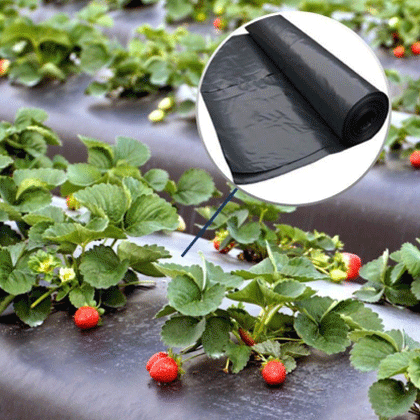

Agriculture

Common applicationsp