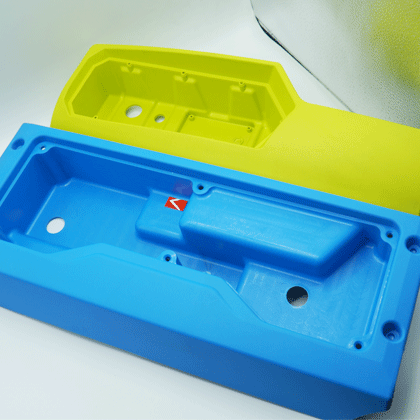

Extrusion is a method of plastic formation including 2 phases: extruding melted plastic and pressing it into mould for fixed forms. It is widely used in plastic processing, especially in complex components.

RAFFIA

Common applications

Our solutions

Our solutions

Raffia

Common applications

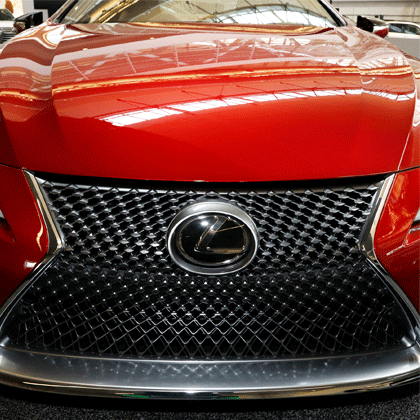

Car & motorbikes components

Common applications

Our solutions

Our solutions

Technical electric components

Common applications