ABOUT Vico’s Vical PP filler masterbatch

PP filler masterbatch brand Vical is a mixture of CaCO3 powder, PP resin and appropriate additives

PP filler masterbatch is made from calcium carbonate (CaCO3), polypropylene (PP) resin and other plastic additives. PP fillers are used extensively in the plastics industry to save cost and enhance productivity.

APPLICATION

PP Filler Masterbatch is a versatile additive widely used in the plastics industry to enhance product properties and reduce costs. Here are some of its key applications:

Packaging Industry

- Plastic Bags: Improves stiffness, tear resistance, and reduces material costs.

- Bottles and Containers: Enhances rigidity, heat resistance, and reduces weight.

- Food Packaging: Provides barrier properties and improves product shelf life.

Automotive Industry

- Interior Components: Used in dashboards, door panels, and other interior parts to reduce weight and improve stiffness.

- Exterior Components: Employed in bumpers, fenders, and other exterior parts to enhance impact resistance and durability.

Construction Industry

- Pipes and Fittings: Improves mechanical properties, reduces material costs, and enhances thermal insulation.

- Building Materials: Used in profiles, sheets, and other building materials to improve stiffness, impact resistance, and fire resistance.

Electronics Industry

- Housing for Electronic Devices: Enhances mechanical strength, thermal conductivity, and flame retardancy.

- Cable Insulation: Improves mechanical properties and reduces material costs.

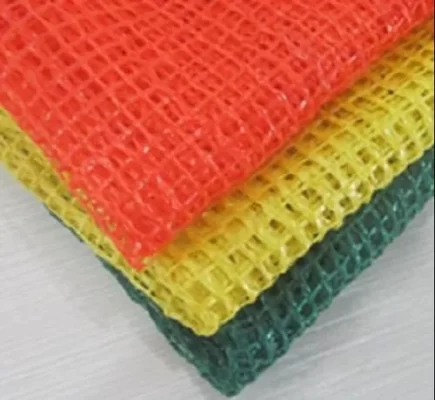

Textile Industry

- Non-woven Fabrics: Used in applications like medical textiles, filtration, and hygiene products to improve strength, stiffness, and thermal resistance.

Other Applications

- Agriculture: Used in films and mulches to improve durability and UV resistance.

- Consumer Goods: Used in toys, household appliances, and other consumer products to reduce costs and enhance product performance.

CONCLUSION

- Vical PP filler masterbatch is an optimal solution for the plastics industry, enabling businesses to reduce costs, enhance product quality, and contribute to environmental protection. The choice of suitable PP filler masterbatch depends on the specific requirements of each application.

Contact us at Vico Plastic Co., Ltd. to learn more about our products.

VICO PLASTIC VIETNAM CO., LTD

(Truong An Industrial Zone, An Khanh, Hoai duc, Hanoi, Vietnam)

Reviews

There are no reviews yet.